Yomura: Your Trusted

Mold Manufacturing Partner

Comprehensive contract mold manufacturing services, delivering high-quality, precise molds. Partner with us for seamless integration into your production processes.

CONTACT USThe Yomura Advantage

Efficient Collaboration

Open communication channels for seamless collaboration and responsiveness.

Global Reach

Strategically located facilities and global presence for efficient logistics and rapid delivery.

Cutting-Edge Technology

Continuous investment in advanced machinery and design software for industry-leading capabilities.

Collaborative Partnerships

Localized Presence

Joint operations with mold makers in key regions for a localized presence and enhanced customer service.

Global Services

International offices and service centers to effectively serve customers worldwide.

Contract Mold Manufacturing Process

Customer Provides CAD File

3D CAD file enables accurate mold fabrication quotes.

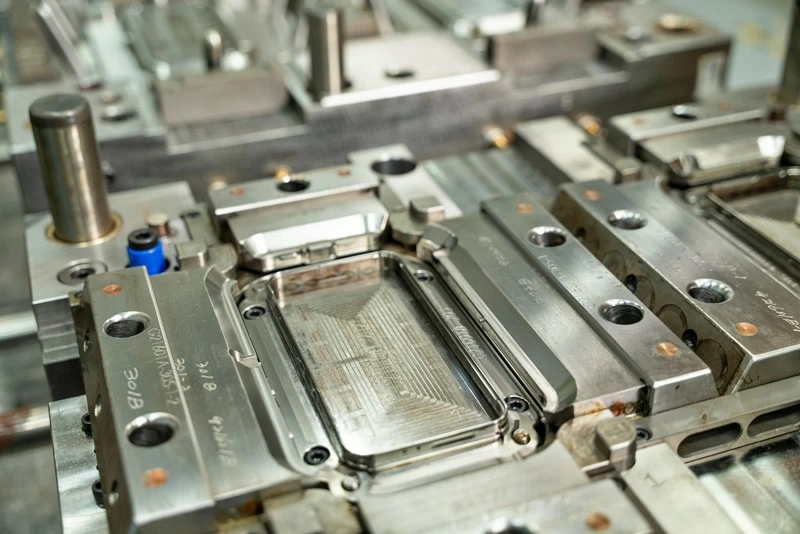

Comprehensive Mold Design

3D mold design shared with customer for review and approval.

Pilot & Short Production Runs

Conduct quality assurance runs post-mold fabrication completion.

Tooling Prepared for Delivery

Prepare tooling for delivery upon customer's sample approval.

Adherence to Quality and Timelines

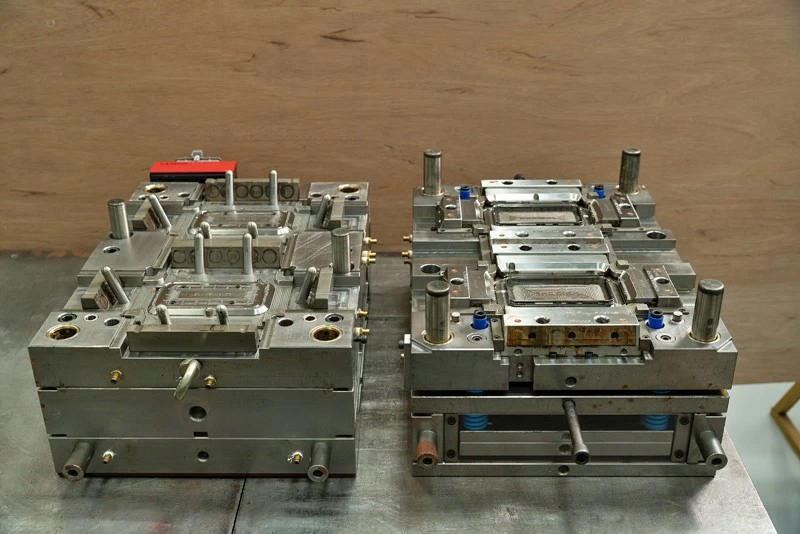

High Precision Molds

Meticulously crafted molds to precise customer specifications.

Reliable Delivery Schedules

Prioritization of adherence to agreed-upon delivery timelines.

Value-Driven Services

Cost-Effective

Swift and affordable mold fabrication without compromising quality.

Long Life-Cycle

Durable molds designed for prolonged life cycles and minimal maintenance.

Project Management Support

Comprehensive design and project management to streamline the mold manufacturing process.

Offshore Molds Examples

Exceptional Customer Value

Early Involvement in Design

Collaborative approach from project inception for comprehensive understanding of customer needs.

Globally Competitive Pricing

Highly competitive pricing structure for exceptional value to customers worldwide.