Liquid Injection Molding (LIM) Expertise

Discover the pinnacle of silicone and rubber manufacturing with our cutting-edge Liquid Injection Molding and Transfer Molding processes.

CONTACT USAdvantages and Applications

At Yomura, we utilize premium materials from reputable manufacturers, including Shin Etsu, Dow Corning, and GE Silicones, to ensure the highest quality and performance of our products.

Low Viscosity and Injection Pressure

Our processes are suitable for silicone molding due to the low viscosity and lower injection pressure required.

Chemical Stability & Green

Our products offer excellent chemical stability and are environmentally friendly.

High Dimensional Accuracy

Our manufacturing processes ensure high dimensional accuracy for precise and consistent product quality.

Efficient Production

Our processes produce high-quality parts without the need for secondary finishing, allowing shorter production cycles compared to other methods.

Over-molding Capabilities

We offer over-molding services, combining silicone or rubber components with hard plastic frames (such as PC or ABS) for applications like waterproof devices, shock-proofing, and shielding.

Thin Wall Design

Our expertise allows us to create very thin wall designs (as thin as 0.25mm) for silicone adhesion to plastic housings, meeting the demand for low-profile product designs.

Waterproof Features

We can create waterproof features by combining soft rubber contacts with constant pressure provided by hard plastic housings (ribs).

Shin Etsu

Our selection includes materials from Shin Etsu, known for their superior quality.

Dow Corning

We use Dow Corning products to ensure high performance in our manufacturing processes.

GE Silicones

GE Silicones are part of our premium materials, contributing to the durability and reliability of our products.

Diverse Material Expertise

Silicone Varieties

Working with different types of silicone, including SinEtsu and Momentive.

Specialized Rubbers

Chloroprene Rubber, Neoprene, and Fluorine Rubber are among the materials we handle.

Advanced Elastomers

Our expertise extends to Ethylene Propylene Diene Monomer (EPDM), FPM, Viton, Fluorel, HNBR, and NBR.

Comprehensive Process Offerings

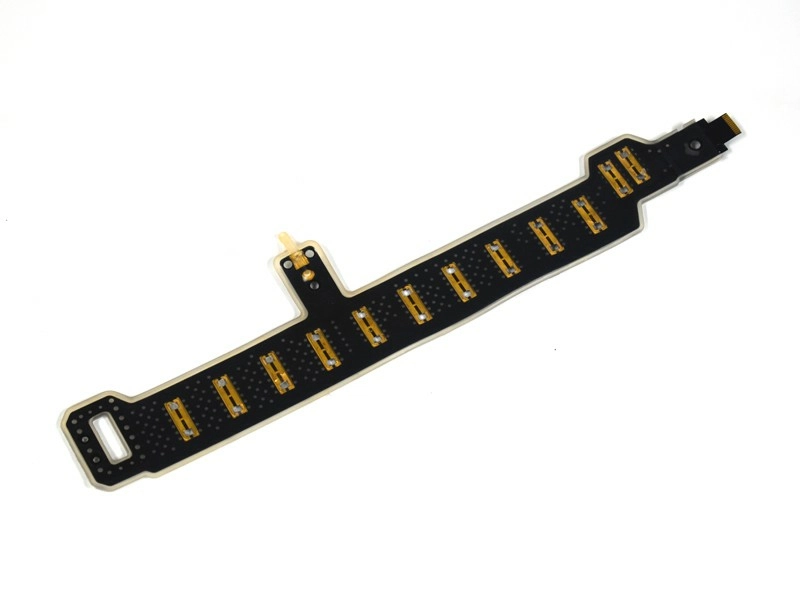

Overmolding

Silicone/Rubber to Plastic, Metal, and other substrates.

Insert Molding

Silicone/Rubber to Metal, Plastic, Teflon, Aluminum, TPU, and more.

Rubber Mounting

Silicone/Rubber mounting on USB devices, electrical components, and other applications.

Our Global Reach and Manufacturing Capabilities

Advanced Manufacturing Facility

Our 300 square meter Class 100,000 clean room is equipped with the latest technology and designed to maintain the highest standards of cleanliness and precision.

Integrated In-House Expertise

Our skilled team handles all aspects of the process, from design and tooling to prototyping and mass production, ensuring seamless service.

Serving Clients Worldwide

With experience serving customers in over 20 countries, we have established a global reputation for excellence in liquid injection molding of silicone rubber.

Industry Applications

Aerospace & Defense

Providing high performance components for critical aerospace and defense applications.

Automotive

Manufacturing durable silicone and rubber parts for the automotive industry.

Medical & Healthcare

Creating safe and reliable products for medical and healthcare uses.

Electronics and Telecommunications

Designing and producing specialized silicone and rubber components for electronic and telecommunication devices, ensuring reliable performance.

Consumer Products

Developing innovative silicone and rubber solutions for a wide range of consumer products, enhancing their functionality and durability.

Commitment to Innovation

At Yomura, we are dedicated to continuous improvement and innovation, ensuring that we remain leaders in delivering high-performance liquid injection molded components for the most demanding applications.

CONTACT US