Micro Molding Mastery at YOMURA

Discover the pinnacle of miniaturization in manufacturing with YOMURA's state-of-the-art micro molding technology.

CONTACT USUnderstanding Micro Molding

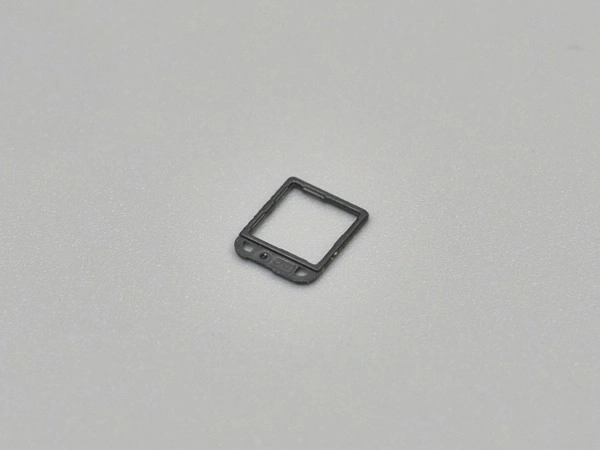

Micro Size

Creating components measured in millimeters, mastering the art of tiny.

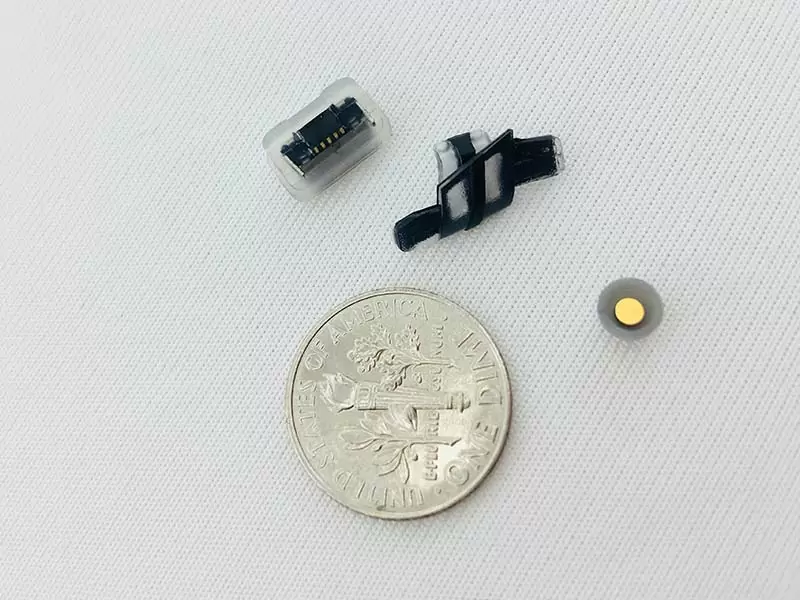

Precision for Micro-Robotics

Manufacturing microscopic gears, links, and transmission components for medical robots and micro-actuators. Our process ensures zero-defect functionality in miniature robot systems where every micron counts.

Micro Tolerances

Achieving precise tolerances measured in thousandths of an inch.

YOMURA's Precision Techniques

01

6:1

Aspect Ratio

02

0.012

Wall Thickness

In inches for ultra-thin parts.

03

0.0004

Tolerances

In inches, for precision down to the smallest unit.

Micro Dimensions in Detail

| Hole Dimensions | as small as 0.008 inches |

|---|---|

| Hole Pitch | as fine as 0.012 inches |

| Wall Thickness Range | Wall Thickness Range |

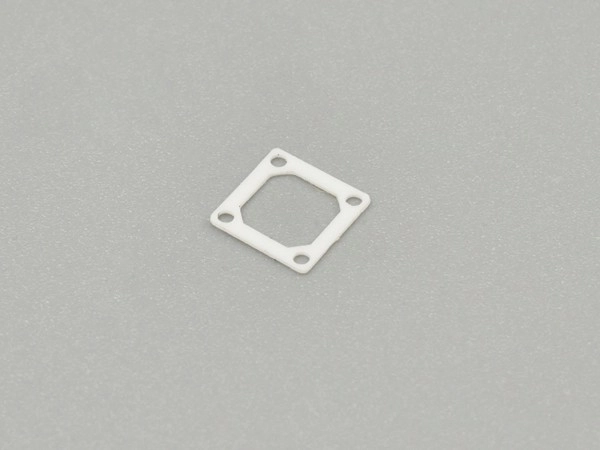

Yomura's Specialty - Micro Double Injection Molding

At Yomura, we specialize in advanced injection molding techniques for precision micro parts and components. While micro single injection molding is widely used, we have pioneered expertise in the rare and challenging process of micro double injection molding.

Benefits

This advanced molding technique unlocks unique capabilities for innovative micro product designs:

- Combine properties of different materials (rigid/soft, opaque/transparent, etc.)

- Add functions like colored accent regions, overmolded grips, windows, etc.

- Improve bonding strength compared to adhesive joining

- Streamline manufacturing by molding multi-material parts in one operation

Industries Revolutionized

Double injection molding is ideal for micro components that require complex geometry, multi-materiality, and tight tolerances, such as:

Micro-Robotics & Medical Automation

Producing high-precision functional parts for surgical robots and capsule robots. Utilizing engineered plastics to replace metal in micro-drive systems, achieving significant weight reduction without compromising precision.

Automotive & Aerospace

High precision components for modern engineering marvels.

Pushing the Boundaries

While complex, micro double injection molding provides key advantages over other bonding techniques for micro manufacturing. Our expert molding teams have mastered this difficult process through extensive experience and investment in leading-edge micro molding equipment.

Partner with YOMURA

Your Project, Our Precision

Collaborate with our experts to transform your innovative ideas into micro molded realities.

Industry-Leading Standards

Tap into YOMURA's adherence to stringent industry protocols for unparalleled quality control.

Comprehensive Solutions

From consultation to creation, benefit from our all-encompassing approach to micro molding.

CONTACT US